Recommendations and tips

Recommendations and tips

The advantages of classifying air filters according to ISO 16890

To ensure the quality of a service or product ISO standards were incorporated into most businesses. An ISO standard means that a service or product complies with the general expectations concerning safety, durability and effectiveness.

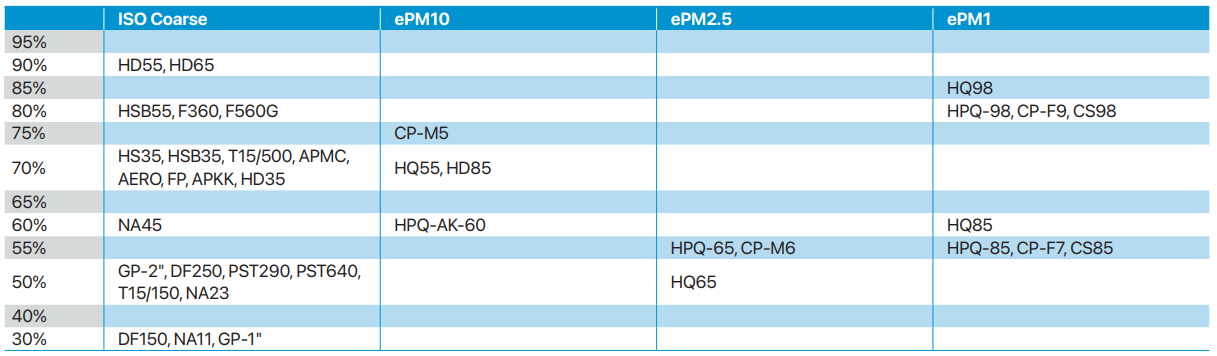

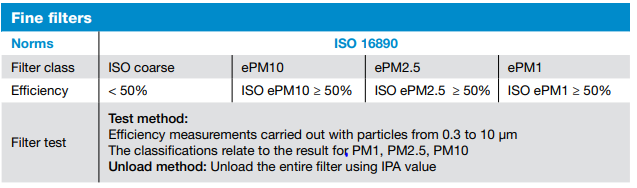

ISO 16890 classifies air filters into 4 groups. To fall into a certain group, a filter must capture at least 50% of the respective particle size. If a filter catches more than 50% of the PM1 particles, it is an ISO ePM1 filter. If a filter catches less than 50% of the PM10 particles, it falls under the ISO Coarse filters.

A distinction is made within the various groups based on percentage efficiency. We round this percentage down to 5%. If you are looking for a filter that captures 60% of all particles smaller than 1 microns, then choose an ePM1 60% filter. If 80% of those particles have to be stopped, then an ePM1 80% filter is the right option.

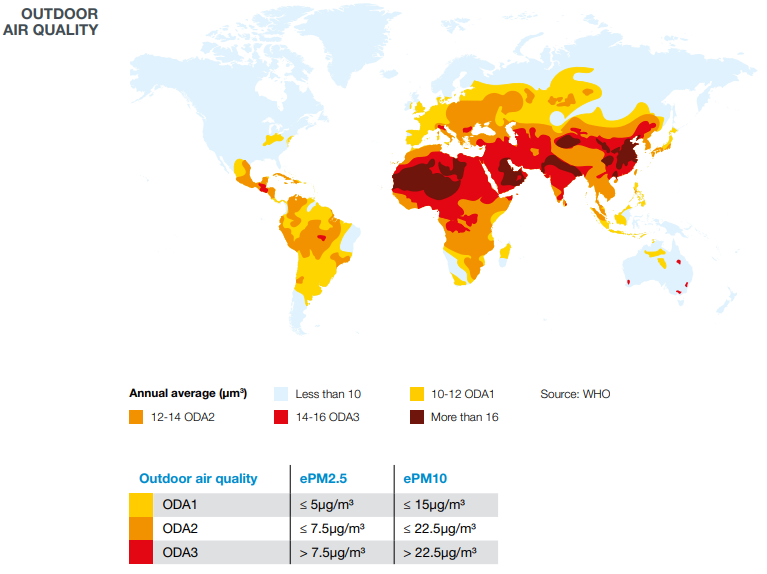

Out door air quality

92% of the world’s population lives in places where air quality guidelines are not respected. In fact, a great deal of research has highlighted specific areas where air quality levels do not meet the limits set by the WHO. This map shows the extent of the problem in France.

How do I choose the right filter?

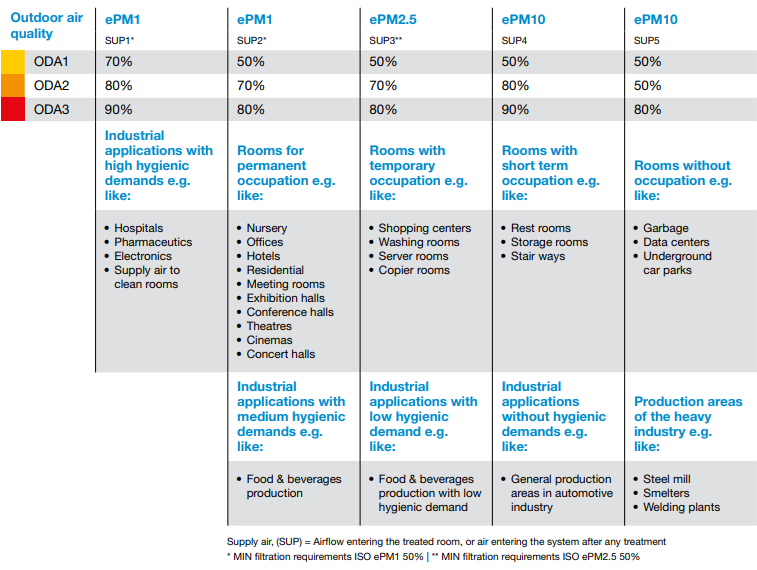

Eurovent has drawn up a guideline for selecting air filters based on ISO 16890; Directive 4/23-2022.

The table below shows how the different filter classes relate to the quality of the outside air and

the desired classification of the supply air.

It is therefore essential to take these parameters into consideration when choosing an air filter because, over and above the financial aspect, its filtration efficiency and energy consumption are decisive.

Classification and AFPRO products range