Gas turbines

Air filtration in gas turbines

Gas turbines are highly efficient, but sensitive machines that operate all over the world in some of the most challenging environments; from the dry, hot and dusty deserts to the rain, fog and salty winds of offshore locations.At AFPRO Filters, we offer a product range of unique filters that protect gas turbine installations from damage caused by erosion, corrosion and fouling. As a result, we improve the reliability, extend the service life, reduce downtime and limit the maintenance needs of your machines.

The importance of air filtration in gas turbines

Effective air filtration is critical to the overall performance, reliability, longevity and profitability of gas turbines. By choosing the right filter, you protect the gas turbine, the generator and the system from the effects of dirt, contaminants and airborne particulate matter.

Air filtration:

- Protects compressor rotor and stator blades from damage.

- Keeps compressor efficiency high.

- Keeps cooling passages open.

- Maintains the output performance of the gas turbine.

Air filtration ensures the continued performance of gas turbines in any environment, even in the most extreme climatic conditions.

Our main solutions for gas turbines

The three main products we offer at AFPRO Filters are:

The problems we solve with our products

Foreign objects, often large in size, entering your system cause the most catastrophic damage to your gas turbine installation. This problem is the result of poor plant maintenance, as these are easily filtered out.

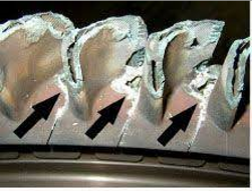

Erosion, caused by particles of 5 µm or more, blunts the leading edges of compressor blades. This in turn reduces efficiency because blade thinning increases thermal fatigue.

Corrosion, caused by solvated salts suspended in an air stream, can oxidize compressor blades and reduce efficiency. This occurs primarily in offshore and coastal applications, or in turbine sections where sulfur is presence in the fuel source.

Fouling is the most common cause of performance loss in gas turbines. In total, 70% of all gas turbine power losses are due to compressor fouling. It’s smoke, oil vapors and various contaminants that can cause fouling, allowing particles as small as 5 µm to adhere to rotor and stator blades, reducing compressor efficiency.

Effective filtration is essential to protect your gas turbines and prevent downtime. And our filtration solutions deliver!

Different types of gas turbine installations

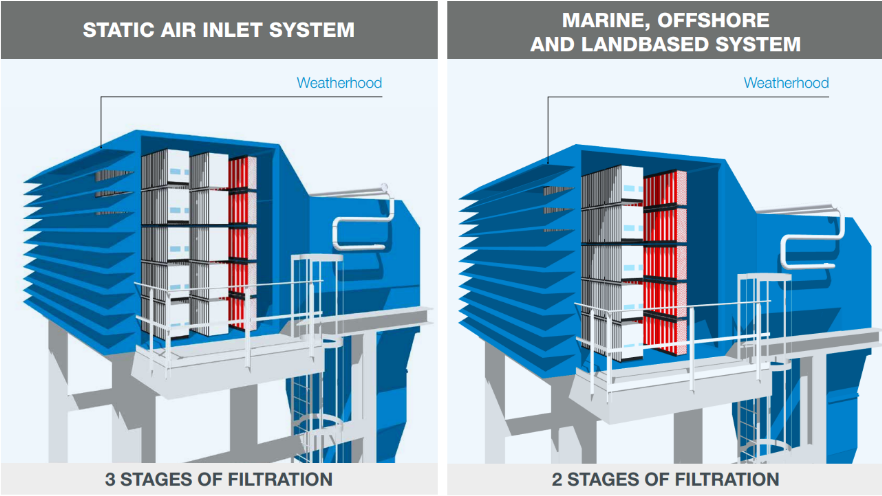

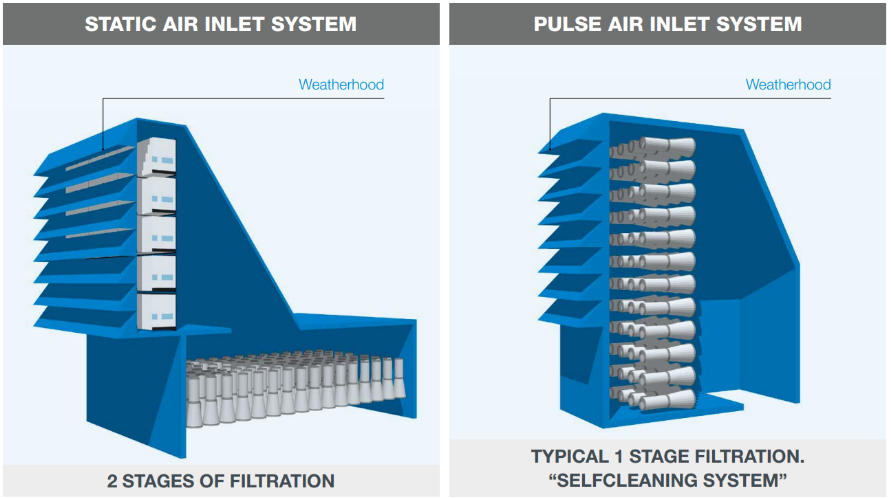

The following images show the typical filtration systems that can be found in turbomachinery. Our unique air filters protect all these filtration systems from damages and contaminants, extend the service life of the equipment, improve the availability and reduce the need for maintenance.

The benefits of choosing AFPRO Filters for your gas turbine filters

- A complete product range adapted to extreme environments

Our product range meets all the needs of the gas turbine market, from static air intake to pulsed air intake, in environments ranging from rural to the most extreme (Arctic, desert).

- Unique solutions

We offer the unique Drop Safe® product: with a unique media design and continuous performance in wet and mist conditions (tested according to ISO 29461-1).

- Tested by renowned manufacturers

Our products meet the most stringent requirements of OEM gas turbine manufacturers for burst strength, particle filtration efficiency and service life.

The solutions we offer at AFPRO Filters enable you to extend the service life of your gas turbine installations and reduce maintenance costs.