ISO 29461 standard

ISO 29461-1 and ISO 29461-2 are the first international test standards that offer a uniform testing method to help operators make a more efficient selection of air filters. ISO 29461-1 is the standard for filter efficiency and dust holding capacity for turbomachinery. And ISO 29461-2 is the standard for filter performance in fog and mist conditions. Both standards combine a number of other ISO standards and relate better to the actual performance of gas turbine installations.

ISO 29461-1 standard

ISO 29461-1 specifies methods and procedures for determining the static performance of air filters used in the intake air filtration systems of stationary gas turbines, compressors, and other stationary internal combustion engines.

This standard applies to:

- EPA or HEPA air filters that have an efficiency of 85% or greater for MPPS and are tested in accordance with ISO 29463.

- Lower efficiency filters that are tested in accordance with ISO 16890.

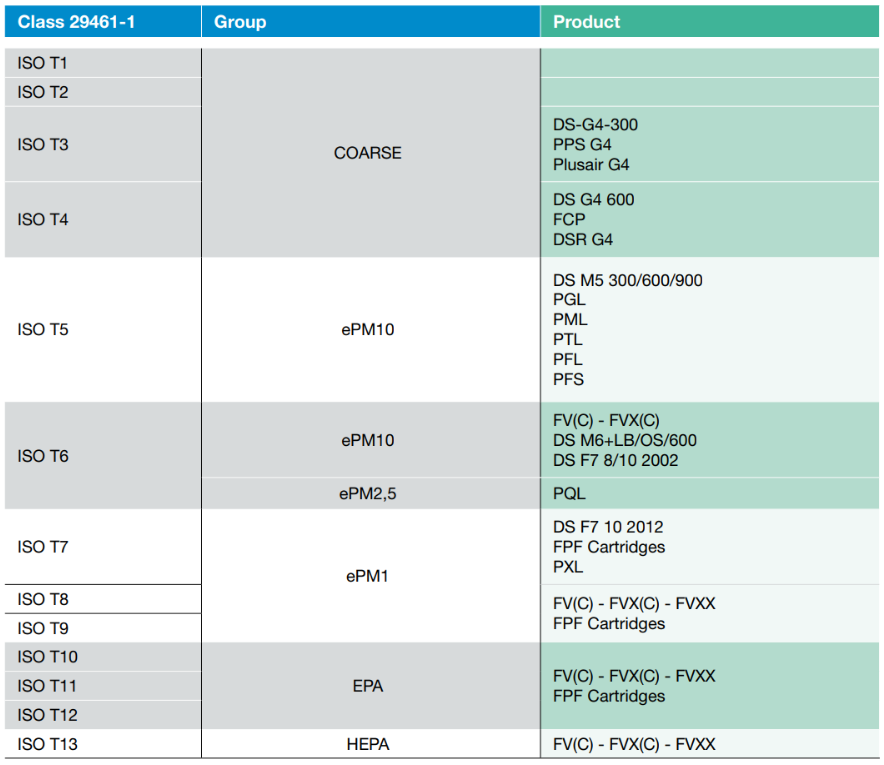

ISO 29461-1 defines 13 classifications, from T1 to T13 in ISO 29461-1, based on test results according to ISO 16890 and ISO 29463. It indicates the efficiency of a turbomachinery air intake filter for a given range of particle sizes: coarse, ePM10, ePM2,5,min, ePM1,min or MPPS (most

penetrating particle size).

This standard does not provide a method for directly measuring the performance of the entire filtration system as installed, unless it can meet the qualification criteria of the test set-up. However, the cumulative efficiency of air filters in multi-stage fine filtration systems can be calculated using the methods described in ISO 16890-1.

ISO 29461-2 standard

ISO 29461-2 provides a comprehensive test method on fog and mist performance. It indicates the efficiency of the filter in extreme conditions.

Test procedure:

ISO 29461-2 requires filters to be measured and evaluated according to the following test parameters:

- The test duration is 4 hours.

- The filter must have a pressure drop of less than 1000 Pa (4” w.g.).

- There cannot be any measurable water downstream of the filter.

- Optional test method if a filter is to be labeled “Hydrophobic”: use a water dye to confirm that there is no water downstream of the filter.

A filter passes the fog and mist endurance test if it meets criteria 1-3. A filter is considered as

“Hydrophobic” if it meets all 4 criteria.

Consider both the ISO 29461-1 efficiency standard and the ISO 29461-1:2 hydrophobicity standard when selecting a filter!

Learn more about our solutions for wet environments such as gas turbines here.